OUR SERVICES

Service allows TGE to consider each of its clients’ questions.

TGE thus seeks to be efficient and professional in order to provide responsive answers by deploying specific services.

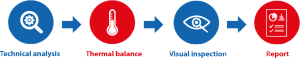

Technical audits

Technical audits

TGE regularly does detailed technical audits in evaporation, crystallization and drying to help the diagnosis of the difficulties encountered, and to remind operation principales.

During each audit, a thorough technical analysis is performed (reinforced by doing thermal balance of the real and theoretical operation of the facilities) in order to demonstrate problems and report on the difficulties encountered.

A visual inspection of the overall condition of the facility is also performed.

At the end of this audit, a full quality report, accompanied by photographs, is sent to the customer. Each report sets out an exhaustive list of solutions to be implemented and prioritizes the actions to be taken.

We provide to our customers our solid expertise concerning energy efficiency, driving modes, washing optimization and capacity gains, maintenance, hygiene and safety of the evaporation and drying facilities.

Multi site technical audits help customers think about an overall industrial strategy.

For any additional information concerning technical audits, do not hesitate to contact us.

Training

Training

TGE is a certified training company in France, which allows it to intervene as a true professional in the fields of evaporation, crystallization and drying.

All our trainings are delivered by qualified engineers close to the field, thus benefitting from great experience in the area concerned by the training. This experience is used to address the different themes of the training and to send strong messages to your teams.

Our training courses allow grasping these three following points:

1. The basic principles, physical phenomena in play, theoretical exercises;

2. The general principles of management and maintenance;

3. Knowledge that allows ensuring the facility diagnosis.

This theoretical part may be accompanied by a practical part on the site.

These trainings are intended for a variety of audiences: production operators, maintenance technicians, team leaders, management staff and industrial management.

The training program is adapted for each customer, based on their teams, their needs and the nature of their evaporation and drying facilities. The positive impact of our training is immediately measurable and is a long-lasting, sustainable process (product quality, energy consumption, maintenance optimization).

Specific studies

Specific studies

- Preliminary project engineering

TGE is able to help you to define your project and your needs accurately and in detail. Our process engineers and design office will accompany you all throughout the definition of your project - Digital flow simulation

In order to address any particular problem, TGE is able to perform digital flow simulations. This confluence of digital tools and technical expertise allows TGE to bring precise and detailed responses to your questions.

- Vibrations, noise, vacuum resistance…

TGE is able to offer you detailed study services to respond to specific problems. We are able to offer you services for :

– vibration analysis;

– noise studies;

– looking for air intakes (vacuum capability);

– Atex

– the environment (bag filters)

– compliance / safety (for example: hose reel)

– LCC (Life-Cycle Cost)

– engineering studies

– time of return on investment

– eco-design

Energy savings studies

Energy savings studies

Aware of a policy of reduction of energy costs on industrial sites, TGE studies feasible energy savings with modern solutions by doing energy mapping.